Structural Engineering Behind the Pry Resistance of Modern Entry Doors

Aug 15, 2025

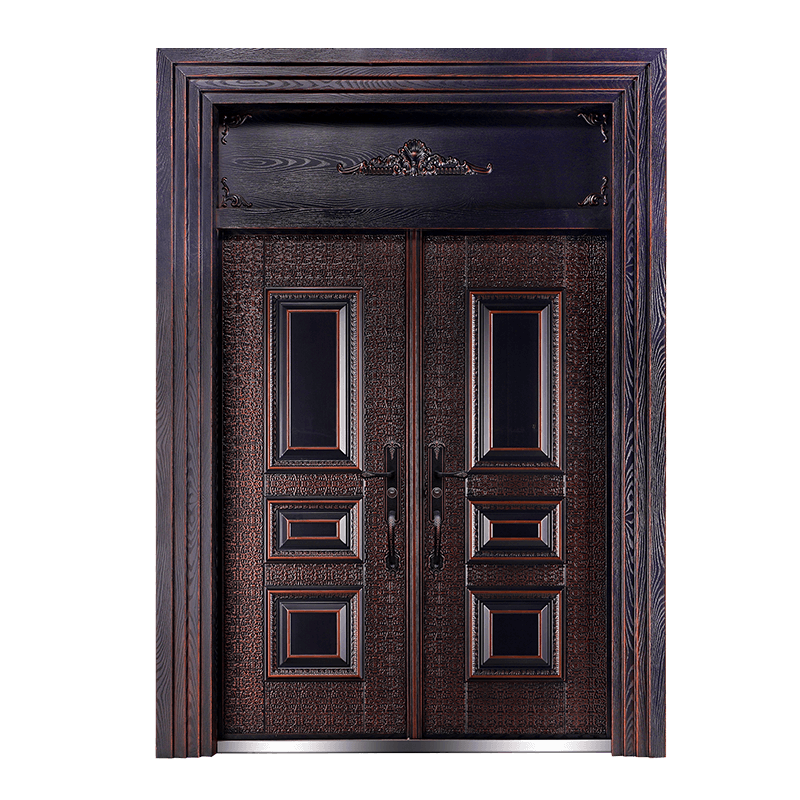

The Entrance Anti-Theft Door is a vital element in home and commercial security architecture, designed to resist not only forced entry but also subtle prying attempts that are commonly used by intruders. With burglary techniques becoming increasingly sophisticated, door manufacturers have responded by reinforcing structural elements to deter tampering. The effectiveness of such doors lies not merely in the lock or the surface material but in a carefully engineered combination of mechanical strength, integration, and intelligent design that reduces or eliminates vulnerabilities. Understanding the key structural design features that contribute to anti-prying performance is essential for appreciating how these doors protect occupants and property.

Multi-Point Locking Systems and Internal Reinforcements

One of the core features that enhances pry resistance is the incorporation of multi-point locking mechanisms. Instead of relying on a single central lock, these doors utilize systems that secure the door at multiple locations along its height, typically the top, center, and bottom. This prevents the door from being wedged open at a single weak point. Additionally, reinforcement bars or steel plates are often embedded along the frame and hinge areas. These internal reinforcements ensure the door cannot be bent or warped under pressure, which is a common prying technique. Combined, these elements form a distributed defense line that resists leverage-based attacks.

High-Strength Hinges and Concealed Hinge Design

Hinges are often targeted during break-ins, making them a critical area for structural fortification. High-end doors are equipped with stainless steel or alloy hinges that are not only strong but also designed to resist torque. More importantly, many designs incorporate concealed or internal hinge systems that cannot be accessed from the outside. This eliminates the risk of hinge-pin removal, a classic prying method. Some doors also feature interlocking hinge sides that physically lock into the frame when closed, offering an additional level of security by making forced detachment virtually impossible.

Anti-Pry Edge Design and Door Leaf Thickness

Another vital structural aspect is the door’s edge configuration. Anti-pry flanges are often added to the door leaf and frame to create overlapping zones that leave no gaps for inserting prying tools like crowbars. In conjunction with this, the thickness of the door leaf itself plays a major role. Thicker leaves, especially those made from cold-rolled steel or composite steel layers, offer significant resistance to bending and denting. Many doors also include internal honeycomb or steel plate cores that distribute impact force and reduce susceptibility to localized pressure from tools.

Reinforced Lock Boxes and Strike Plate Zones

The locking area is typically the stressed section during a prying attack. To mitigate this, modern anti-theft doors are designed with reinforced lock boxes that are embedded within the door’s steel structure, making them more resistant to drilling and force. The strike plate, where the locking bolt connects with the frame, is also fortified using hardened steel and is usually anchored with long screws into the wall studs or reinforced steel tubing. These enhancements ensure the locking mechanism is not a weak point and can withstand concentrated force without failure.

Full-Metal Frames and Installation Precision

Finally, the overall doorframe and its installation quality significantly affect anti-pry resistance. Full-metal frames, often made from galvanized steel or alloy composites, provide a rigid base structure that complements the door’s leaf strength. Inadequate installation can create spacing or alignment flaws, which intruders can exploit, so high-precision installation with secure anchoring into the wall structure is critical. Expansion bolts, welds, or chemical anchors are often used to fix the frame in place permanently. These practices ensure that the frame doesn’t shift or flex, maintaining integrity under external force.

English

English 中文简体

中文简体 Français

Français Español

Español عربى

عربى