Durability and Rust Resistance of Spliced Door

Feb 13, 2026

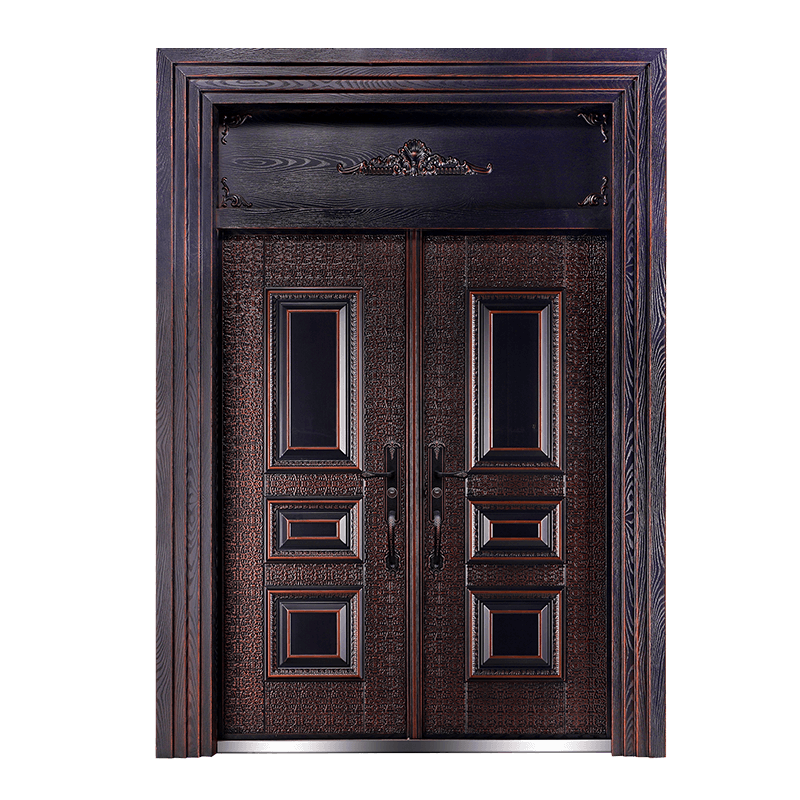

Introduction to Spliced Door

A Spliced Door has gained popularity in modern homes and commercial spaces due to its combination of materials and cost-effectiveness. Unlike traditional single-material doors, a Spliced Door integrates different sections, often combining wood, metal, or composite materials to achieve both aesthetic appeal and functional performance. One of the common questions homeowners and builders have is whether a Spliced Door is resistant to rust and built for long-term durability. Evaluating its materials, manufacturing process, and environmental factors is crucial in understanding its performance over time.

Rust Resistance of Spliced Doors

The rust resistance of a Spliced Door largely depends on the materials used, especially if metal components are present. Steel or iron elements in a door are susceptible to rust when exposed to moisture or humid conditions, particularly in bathrooms, kitchens, or outdoor entrances. However, many Spliced Doors include treated metal sections with protective coatings such as galvanization, powder coating, or anti-rust paint. These protective layers prevent oxidation and significantly extend the door's lifespan. Additionally, some designs isolate metal sections from direct water contact by integrating wood, plastic, or composite panels, reducing the risk of corrosion. Proper installation, including sealing edges and joints, further enhances rust resistance.

Durability and Structural Strength

Durability is another critical factor when assessing a Spliced Door. By combining different materials, manufacturers aim to balance structural strength and visual appeal. Metal sections provide rigidity and resistance to impact, while wood or composite panels contribute to flexibility, insulation, and aesthetic design. A well-constructed Spliced Door can withstand daily wear and tear, including repeated opening and closing, minor impacts, and environmental stressors. It is essential, however, to ensure that all materials are of high quality and properly joined to prevent weak points that may compromise the door's performance. Low-quality adhesives or improper splicing can reduce durability and increase maintenance requirements.

Maintenance and Longevity

Even though Spliced Doors can be highly durable and rust-resistant, regular maintenance is necessary to ensure suitable performance. Cleaning the door surfaces to remove dirt, moisture, and debris prevents long-term damage. Periodic inspection of metal components for signs of corrosion or coating deterioration allows timely touch-ups. Wooden or composite panels should be treated with sealants or finishes to prevent swelling, cracking, or fading. With proper care, a high-quality Spliced Door can last many years, providing reliable functionality and preserving its appearance. Environmental conditions, such as high humidity, bad temperatures, or direct exposure to rain, can affect longevity, so selecting a door designed for the intended environment is important.

A Spliced Door can be both rust-resistant and durable if it is made from high-quality materials and includes appropriate protective treatments. Metal sections with anti-corrosion coatings, combined with properly sealed wood or composite panels, ensure structural strength and longevity. Regular maintenance further enhances its performance, making it a practical choice for a wide range of applications, from residential interiors to commercial entrances. Understanding the materials, construction quality, and environmental conditions is key to selecting a Spliced Door that meets expectations for both durability and rust resistance.

English

English 中文简体

中文简体 Français

Français Español

Español عربى

عربى